LN83 series cage guided globe control valves are single-seat LN8 series pressure balance control cage valves, one of the three largest base type products. Use separate sleeves, large guide structure, balance pressure sealing ring, high-performance nonmetal sealing ring, has good dynamic stability, high control precision, allow the pressure difference is big, the operating force is small, large flow capacity, etc. Suitable working conditions of normal temperature, differential pressure, under the action of alternating stress control.

Product Description

The LN8 series sleeve-guided control valve is a sleeve-guided, pressure-balanced single-seat control valve. It is TÜV ISO 15848 certified in 2019. It has a split sleeve construction and a high performance balanced seal ring seal. Suitable for fluid control in ambient and priming conditions. Bellows seal type is available. Thousands of applications in the fine chemical, petrochemical, pharmaceutical and other industries.

Modular design concept, combining the American and Japanese schools of high-precision control and the German school of modular concept.

The cage valve inner cavity of the valve body is S-shaped distribution, smooth and without dead ends; there are guide wings inside the valve body, which can reduce the mutual force of the medium inside the valve body and reduce the occurrence of cavitation.

The use of sleeve guidance, large guide diameter, smooth guidance, with good dynamic stability.

The cage valve seat adopts floating design, while the sealing surface adopts tapered form to ensure good alignment of the sealing sub.

Sleeve window control flow characteristics, flow characteristics control accurately.

The structure of the inner part is balanced, allowing a large differential pressure, small operating force and large flow capacity.

Equipercent, linear and quick-open flow characteristics are available.

Good use in the temperature range of -80 to 593℃.

And pipeline connection with RF, RJ, FM and other flange type and SW, BW welding type.

The flange distance conforms to GB/T 17213.3-2005 / IEC 60534-3-1:2000; or ISA S75.03-1992 standard.

1. Valve Trims

According to the needs of the working conditions, different materials and surface hardening treatment can easily be chosen to meet the requirements of each function module of trim to improve its performance of the corrosion, cavitation and erosion resistant, lengthen service life.

2. Valve body

The body of LN8 series control valves consists of two passages from upper and lower, forming a shape like letter "S". The design of an elliptical section reduces the flow resistance and turbulent flow to keep the flow fluent. The flap in the middle of upper passage can reduce the eddy flow and increase the flow capacity.

3. Actuator

The standard mate of LN8 series is AM8 Multi-spring pneumatic diaphragm actuator, which can be used in many conditions with the features of strong output force, high reliability, long lifespan and extensive application. The output force changes with the number of springs. The high stress resistant diaphragm, bearing maximum pressure of 0.5 MPa air supply, gives control valve a reliable shutoff. This type of actuator has a long life cycle with more than 1 million times.

1. Structure

A. New function modular design B. Self-centring seat design

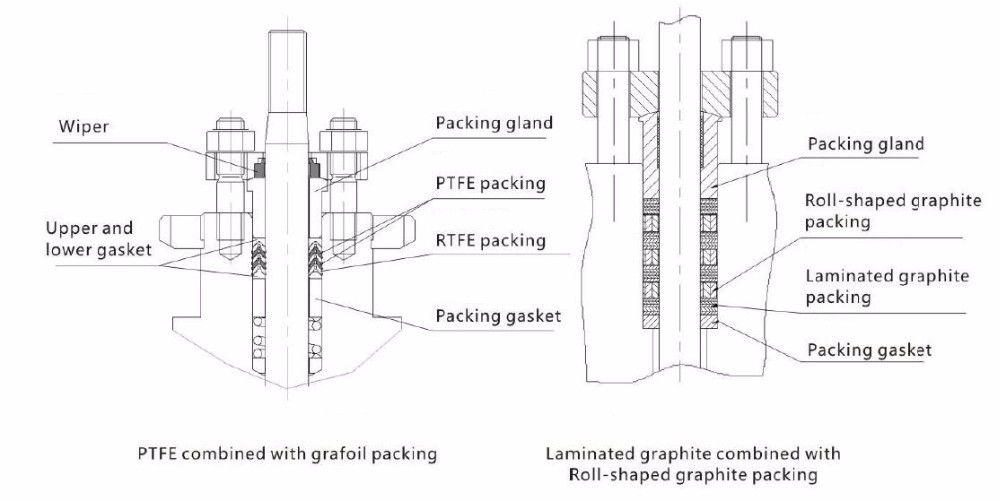

2. Packing system

The packing box assemblies are also optimized. Seal ring in the gland flange can prevent the dirt from entering and protect the packings. The V-ring is added with an U-groove and its angle is changed from conventional 90 to more efficient 85. The packing is a combination of alternating pure PTFE and PTFE with grafoil. When the temperature of fluid is above 200℃, the packing will be made by grafoil.

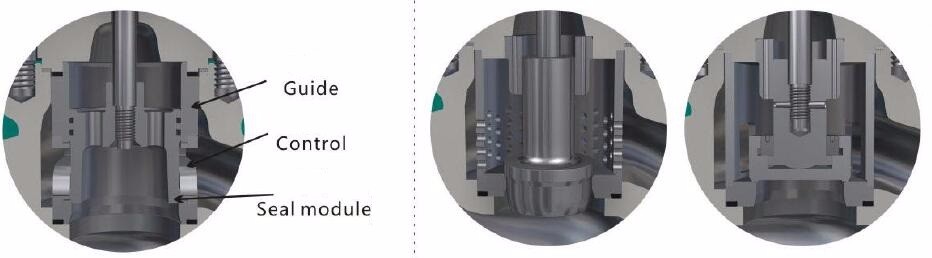

LN8 series control valves are designed strictly on the basis of the IEC standard. They are the latest self-innovated modularized straight stroke control valve of SUPCON. We divide the trims into three modules, namely guide, control and seal module. We provide the best solution according to the function of each module and make action, control and seal more reliable.

Each index, linear, hysteresis, dead zone and leakage, for example, is full compliance with national standards.

Note: For below measured results, take LN8100 top guide single seat valve (PN110) as an example.

Test Items | National Standard | SUPCON Standard | Measured Results |

Seat Leakage | 0.06 L/min | 0.064 L/min | 0.01L/min |

Rated Travel Error | +2.5% | +2% | 1.32% |

Start Error | ±2.5% | ±2% | 0% |

End Error | ±2.5% | ±2% | 0.08% |

BasicError | ±1.5% | ±1% | -0.52% |

Hysteresis | 1.5% | 1% | 0.16% |

Dead Band | 0.6% | 0.4% | 0.38% |

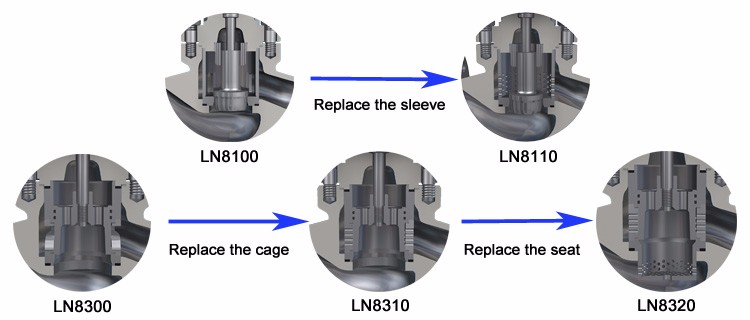

The unique platform and modul design make it easy to remove and displace the parts without special tools, and moreover, easy to change the type of the valve only by changing few parts. A variety of material combinations is optional for the parts.

Sinosteel Equipment Co., Ltd, steam control valve spare parts

Ltd., 100,000 tons of coke oven tail gas to methanol project additional valves

Liaoning Baolai Bioenergy Co., Ltd, new modified asphalt plant project

Ningbo Huatai Shengfu Polymer Material Co., Ltd, 700,000 tons of young hydrocarbon using 400,000 tons/year polyethylene plant GLOBE Control valve

As a Professional Cage Guided Globe Control Valve supplier in China, Welcome new and old customers to consult us!

TECHNICAL PARAMETERS

| Nominal Size | DN40 ~ DN400() |

| Pressure Rating | PN16/25/40/63/100;CL150(PN20)/300(PN50)/600(PN110) |

| Operateing Temperature | -40℃~ 150℃ |

| Characteristics | Equal percentage, linear, quickly open |

| Rangeability | 50:1 |

| Seat Leakage Class | ANSI B16.104: IV、V、VI |

| Body Material | WCB/WCC/LCB/LCC;WC6/WC9;CF8/CF8M;4A/5A etc. |

| Trim Material | 630/316/316+ST/316nitriding/316+Ni60/316+WC etc. |

| Seal Material | PTFE+ graphite v-shaped packing, flexible graphite ring packing, graphite +PTFE braided packing etc. |

Nominal diameter: DN40/50/65/80/100/125/150/200/250/300/350/400

Pressure rating: ANSI CL150/300/600; DIN PN16/25/40/63

Valve body and upper bonnet material: WCB, WC6, WC9, CF8, CF8M, etc.

Upper cover form: standard type (-17 ℃ ~ +316 ℃); high temperature type (+316 ℃ ~ +593 ℃); low temperature Ⅰ type (-45 ℃ ~ -17 ℃); low temperature Ⅱ type (-100 ℃ ~ -45 ℃); low temperature Ⅲ type (-196 ℃ ~ -100 ℃); bellows type (-45 ℃ ~ +350 ℃)

Packing type: PTFE+graphite V-shaped packing; flexible graphite ring packing; graphite+PTFE compilation packing; etc.

Flow characteristics: equal percentage (%); linear (L)

Adjustable ratio: 50:1

Allowable leakage: metal seal: ANSI B16.104 Class Ⅳ; soft seal: ANSI B16.104 Class Ⅵ

What is cage guided control valve?

The Cage valve is a balanced valve that can be used as a dump valve, pressure regulator, suction controller, recirculation valve, and plunger lift applications. Compared to the stem-guided series, cage guided control valves feature larger trim sizes (available in 2" to 10" end connections) for higher valve coefficients (Cv). Cage guided control valves can be equipped with an optional electric drive or operated with compressed air to meet zero-emission requirements.

How does cage guided control valve work

These cage-guided control valves throttle by exposing more or less the port area in the surrounding cage as the plug moves up and down. The cage is also used to guide the valve plug, so the stem does not need to be subjected to side forces like stem-guided valve designs.

The "T" shaped ports in the cage valve through which fluid flows when the plug is moved up and out of the way:

One advantage of the cage-guided design is that the flow characteristics of the valve can be easily changed by simply replacing the cage with another hole of a different size or shape.

What is the Cage Guided Globe Control Valve application?

Cage Guided control valve size is in common use for 1-12, an actuator for standard diaphragm type. By metal seat, the suitable temperature range is -196 +538, and by soft seat, the suitable temperature range is -45 +200. It's content to most industrial process control.

What is the structure of Cage Guided Globe Control Valve?

The most excellent cage guided control valve is balance characteristic, for plug balance ports function, fluid pressure acted on static unbalance force of plug, it reduced unbalance force, then the valve can be configured actuator smaller than conventional single seat valve.

how to replace cage guided control valve

All that is required to replace a cage guided control valve is to separate the bonnet from the rest of the body, at which point the cage can be removed from the body and exchanged with another cage.

In order to replace the plug of a globe valve, you must first separate the bonnet from the rest of the body, then remove the plug and stem from the actuator stem, taking care not to disturb the packing inside the bonnet as you do so.

After replacing the cage-guided control valve plug, the valve's "base setting" must be readjusted to ensure proper seat pressure and stroke calibration.

what is cage guided control valve

cage-guided control valves are available with balanced and unbalanced plugs. Balanced plugs have one or more ports drilled from top to bottom, allowing fluid pressure to equalize on both sides of the plug. This helps minimize the forces on the plug that the actuator must overcome:

The force produced by an unbalanced plug is equal to the product of the differential pressure across the plug and the plug area (F = PA), which can be considerable in some applications.

Balanced cage-guided control valve plugs do not produce the same force as they balance the pressure on both sides of the valve plug, however, when the valve is in the fully closed position (through the balance port, through the piston rings), they exhibit the disadvantage of having more leakage paths and Catch port

Therefore, balanced and unbalanced cage guided control valve have similar characteristics to dual-port and single-port stem or port-directed globe cage valve, and for similar reasons.

SUPCON is a specialist control valve manufacturer of cage valves designed to meet the critical service process control requirements of a wide range of applications in the oil and gas, petrochemical and power industries.

Headquarter Add.: SUPCON Park, No.309 Liuhe Road, Binjiang District, Hangzhou, 310053, China.

Tel.: +86 571 8111 9774

Fax: +86 571 8111 9737

E-mail: [email protected]