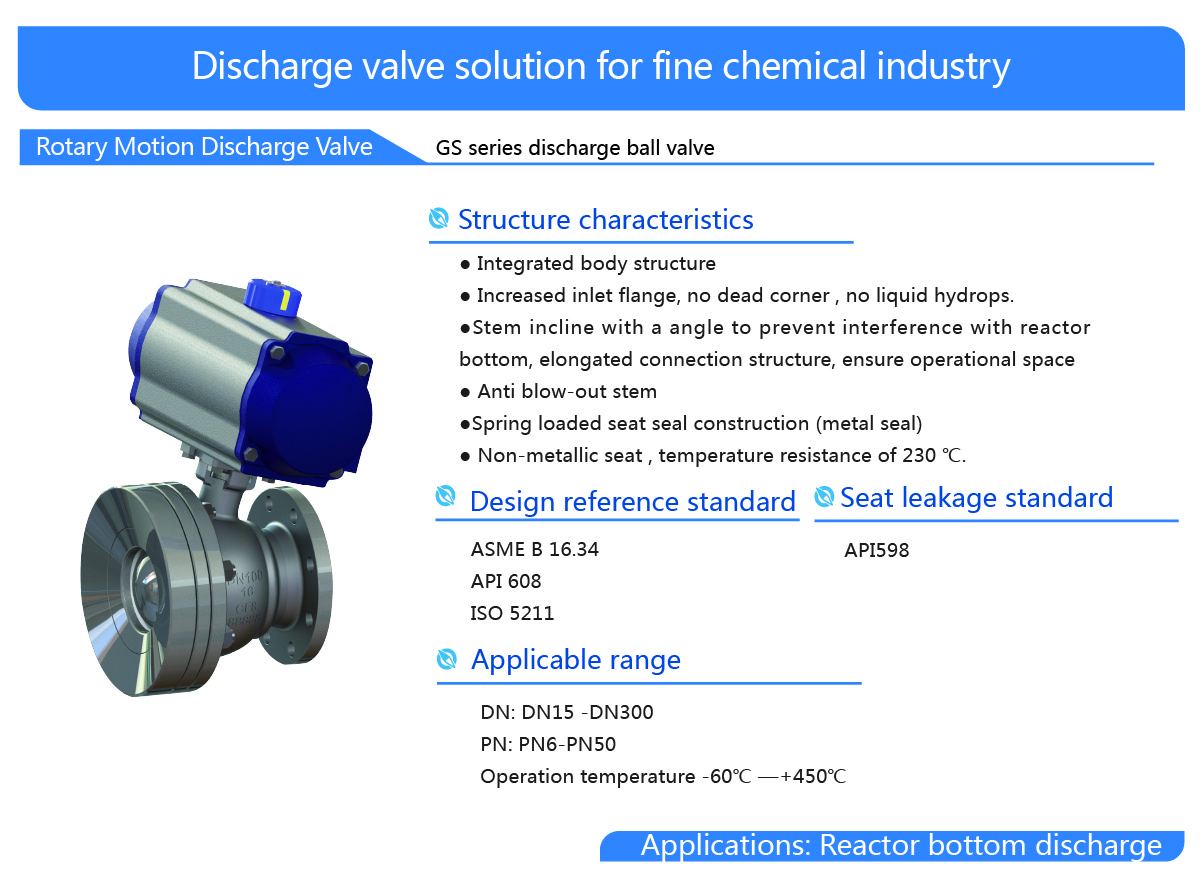

GS feeding ball valve series, one-piece body structure increasing inlet flange design, reduce the valve ball net space, prevent effusion, axis of the stem design a certain Angle, the stretched connection structure, to prevent interference with the bottom of the kettle. Meet the demand of operating space, blow out proof stem, spring loaded valve seat seal structure (hard seal). Non-metallic seat 230 degrees heat resistance.

Product Description

Discharge valves are mainly used for discharging material from the bottom of storage tanks, reactors and other vessels. The valve is connected to the equipment and is located at the bottom by flanging or butt-welding to eliminate the residual phenomenon of process media usually at the outlet of the vessel. According to the needs of the actual situation, it is divided into upward display type and downward display type. The upward type is used for kettle discharge with a stirring discharge valve; the downward type is used for kettle discharge from frame-anchored stirrers.

Integrated body structure

Increased inlet flange, no dead corner , no liquid hydrops.

Stem incline with a angle to prevent interference with reactor bottom, elongated connection structure, ensure operational space

Anti blow-out stem

Spring loaded seat seal construction (metal seal)

Non-metallic seat , temperature resistance of 230℃.

Design reference standard

ASME B 16.34

API 608

ISO 5211

Seat leakage standard

API598

Applicable range

DN: DN15 -DN300

PN: PN6-PN50

Operation temperature -60C -+450C

TECHNICAL PARAMETERS

| Nominal Size | DN40~DN200 |

| Pressure Rating | PN6/PN10/PN16;CL150(PN20) |

| Operateing Temperature | -29℃~316℃ |

| Characteristics | Quickly open |

| Rangeability | / |

| Seat Leakage Class | GB/T 13927-2008: AA、A |

| Body Material | WCB/WCC/LCB/LCC;WC6/WC9;CF8/CF8M;4A/5A etc. |

| Trim Material | 304+ST/304+RTFE etc. |

| Seal Material | PTFE, Flexible graphite |

Headquarter Add.: SUPCON Park, No.309 Liuhe Road, Binjiang District, Hangzhou, 310053, China.

Tel.: +86 571 8111 9774

Fax: +86 571 8111 9737

E-mail: [email protected]