Jan. 07, 2023

Does valve switch still need to be taught? Many people dismiss it, but often the simplest things are also the easiest to make mistakes. For the operators in the plant, a small mistake of their own may pose a danger to themselves. So for your own safety, you must pay attention to every detail. Correct operation is the guarantee of life.

The valve is the control component in the fluid conveying system. It has the functions of cut-off, regulation, diversion, prevention of reverse flow, stabilization, diversion or overflow, and pressure relief.

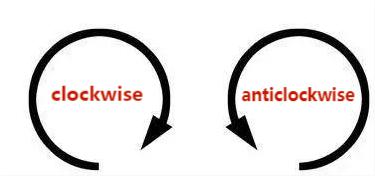

Generally speaking, the valve is basically closed clockwise and opened counterclockwise, or called left open and right closed.

Because most people are accustomed to using the right hand, it is easier to turn clockwise than counterclockwise when using the right hand. Therefore, it is more reasonable to turn the switch counterclockwise to open and clockwise to close in terms of energy-saving or safety.

In addition, most of the screws used in valve materials in our country are right-handed, which is convenient for processing.

Like the one with a hand-wheel, there will be a direction arrow or O→S logo on it (O is on, S is off).

There are really exceptions. For example, some special valves such as spool valves and butterfly valves may be opened clockwise and closed counterclockwise due to the installation position and other reasons. For another example, the pressure reducing valves of oxygen cylinders, hydrogen cylinders, and nitrogen cylinders are opened clockwise and closed counterclockwise.

The high-pressure oxygen cylinder mouth angle valve opens clockwise and counterclockwise to close; the pressure at the outlet pressure reducing valve of the high-pressure oxygen cylinder increases clockwise, and the pressure decreases counterclockwise (closed).

Special valves are generally reversed, and this needs to be paid attention to when opening and closing. Due to the improper installation location, the operator must pay attention to these details. Details determine success or failure, not carelessness. Generally, special valves are marked with the switching direction in obvious positions, and in some places, relevant operating procedures are posted on special valves to prevent misoperation.

In addition, we are a valve supplier, providing various types of valves such as Globe valve, Cage guided valve, Butterfly Valve and etc. Please contact us if you need them.

Improper valve operation can lead to serious accidents, threatening both equipment and personnel safety.

High-pressure gas valves: Incorrect closure may cause sudden gas release, leading to explosions or injuries.

Chemical plant valves: Misoperation can result in leaks, fires, or toxic gas releases, endangering both people and the environment.

Petrochemical pipelines: Incorrect handling can cause backflow or pipeline damage, potentially triggering chain accidents.

Firefighting system valves: Failure to operate as intended may render fire suppression equipment ineffective during emergencies.

Ways to reduce risks:

Check markings and directions: Always confirm the handwheel, lever, arrows, or “O→S” labels before operation.

Observe structure and scales: Use physical indicators or valve scales to verify the status.

Follow standard operating procedures: Adhere strictly to plant or facility guidelines and manuals.

Regular drills and inspections: Train operators periodically to ensure correct response during emergencies.

For household users and novice operators, understanding basic valve operation significantly reduces the risk of accidents:

Check labels: Most valves have arrows or “O→S” markings; always follow them.

Observe handle position: For ball valves, handle parallel to the pipe indicates open, perpendicular indicates closed.

Test lightly: Safely rotate the valve slightly to confirm the operation direction.

Common mistakes:

Assuming all valves follow standard directions and ignoring special designs.

Applying excessive force, damaging handles or valves.

Neglecting daily inspections and operating without checking valve status.

Maintenance suggestions:

Inspect valves regularly for leaks, corrosion, or mechanical damage.

Ensure handles turn smoothly without sticking.

For special valves, post operating instructions at home or on-site to reduce misoperation.

Industrial valves should follow manufacturer-recommended maintenance schedules to ensure safety and performance.

With the rise of industrial and home automation, smart valves are increasingly replacing manual valves, offering safer, more efficient, and convenient operation:

Automated control: Electronic, pneumatic, or electric actuators allow remote operation and precise flow regulation, minimizing human intervention.

Digital monitoring: Sensors track valve status in real-time and issue alerts for abnormalities, reducing potential accidents.

Replacing manual valves: Especially in high-risk or complex systems, smart valves reduce human error and improve both safety and productivity.

Data integration and analytics: Smart valves can integrate with factory information systems, enabling performance tracking, data analysis, and operational optimization.

Home automation: Future residential water and gas systems may incorporate remotely controllable and alarm-enabled smart valves, enhancing daily safety.

Founded in March 1993, SUPCON is one of China’s leading manufacturers and suppliers of automation and process control solutions, serving over 35 countries. Zhejiang SUPCON Fluid Technology Co., Ltd. specializes in industrial control valves, including Globe Valves, Ball Valves, Eccentric Rotary Valves, and Butterfly Valves.

SUPCON combines advanced manufacturing facilities, experienced technical teams, and strict quality control, ensuring reliable, high-performance valves for industrial applications. The company also invests heavily in R&D, holding multiple patents and developing smart valve solutions to meet complex operational conditions.

Headquarter Add.: SUPCON Park, No.309 Liuhe Road, Binjiang District, Hangzhou, 310053, China.

Tel.: +86 571 8111 9774

Fax: +86 571 8111 9737

E-mail: [email protected]