Jul. 06, 2020

Control valve terminology

1. Stroke: To change the flow of fluid, the linear displacement or angular displacement of the components in the valve from the closed position is marked.

2. Quota travel: It is also called quota opening, and stipulates the travel at the fully open position.

3. Relative travel: also called a relative opening, the ratio of the travel of a given opening to the amount of travel.

4. Quota capacity: Under the specified test pressure, the flow rate of the test fluid through the opening of the regulating valve quota.

5. Flow coefficient Kv or Cv:

Kv, the flow coefficient of China. Definition: At a given stroke of the regulating valve, the pressure difference between the two ends of the valve is 100kPa, and the medium density is 1t/m3, the number of cubic meters per hour flowing through the regulating valve.

Cv, the flow coefficient of imperial units. Definition: At a given stroke of the regulating valve, the pressure difference between the two ends of the valve is 1Ib/In2, the temperature is 60 degrees Fahrenheit (F) (15.6 ℃) of water, and the medium density is 834 Ib/USgaI. US gallons.

The relationship between Kv and Cv: Cv=1.16Kv

6. Rated flow coefficient KVmax or Cvmax: Flow coefficient when fully open.

7. Basic error: The regulating valve is the maximum deviation between the actual ascending and descending characteristic curve and the specified characteristic curve.

8. Hysteresis: the maximum difference between two corresponding stroke values of the same input signal rising and falling.

9. Dead zone: The change in the positive and negative directions of the input signal will not cause any limited change in the stroke of the valve stem. Expressed as a percentage of the input signal range.

10. The deviation of the limit stroke: the deviation between the actual stroke at the fully open position and the stroke at the specified fully open position. Expressed as a percentage of quota travel.

11. Leakage: Under the specified test conditions, the test fluid passes

Flow when the regulator is in the closed position.

12. Positive action: When the signal pressure increases, the pushrod moves downward.

13. Reaction type: When the signal pressure increases, the pushrod moves upward.

Inherent flow characteristics: Assuming that the pressure difference between the front and back of the valve is a fixed value, the relative relationship between the relative flow and relative stroke of the medium flowing through the valve is obtained. The quick opening, straight line, equal percentage, and parabola of the flow characteristics in our regulating valve bidding documents all refer to the inherent flow characteristics.

Cv/Cvmax=Kv/Kvmax=f(l/lmax)

14. Working flow characteristics: In actual operation, the pressure difference between the front and back of the regulating valve changes with the flow rate. At this time, the relationship between the relative flow rate and the relative stroke is called the working flow rate characteristic.

15. Adjustable ratio: the ratio between the maximum flow coefficient (CV value) and the minimum flow coefficient (CV value) when the deviation from the specified flow characteristics does not exceed the specified limit. When the flow rate increases to 100 times the minimum controllable flow rate, a valve that can still be well controlled have an adjustable ratio of 100:1. The adjustable ratio can also be expressed as the ratio between the maximum and minimum controllable flow.

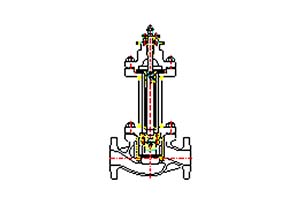

There are many types of regulating valves. If you want to remember these regulating valves faster, comparing memory is a good way. Today is just a brief introduction to the basic knowledge of control valves. If you want to know the selection and installation of control valves and troubleshooting, you can check our other articles. We are a single seat regulating valve manufacturer, if you are interested in our products, please feel free to contact us.

Headquarter Add.: SUPCON Park, No.309 Liuhe Road, Binjiang District, Hangzhou, 310053, China.

Tel.: +86 571 8111 9774

Fax: +86 571 8111 9737

E-mail: [email protected]